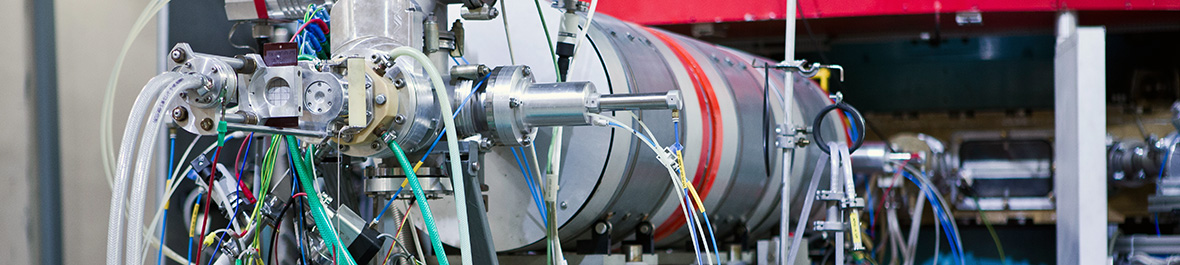

MAUD - SANS Diffractometer

High-resolution SANS diffractometer is one of two experimental facilities operated at the neutron channel HK8. The double-bent-crystal SANS diffractometer MAUD is designed for the measurements of neutron small-angle scattering in the high Q-resolution mode. In contrast to the conventional double-crystal arrangements, the fully asymmetric diffraction geometry on the elastically bent Si analyzer is employed inorder to transfer the angular distribution of the scattered neutrons to the spatial distribution. It enables then to analyze the whole scattering curve by a one-dimensional position sensitive detector.

The instrument is mainly suited to investigation of structural or compositional inhomogeneities in materials in the size range 0.05÷2 micrometer, mainly porous materials and large precipitates in alloys.

The double-crystal diffractometer MAUD ( formerly DN-2 ) is designed for the measurements of neutron small-angle scattering in the high Q -resolution mode. In contrast to conventional double-crystal arrangements (step-by-step angular scanning), a fully asymmetric diffraction geometry on the elastically bent Si analyzer is employed to transfer the angular distribution of the scattered neutrons to the spatial distribution at position sensitive detector (PSD) which enables equisition of the whole scattering curve by a one-/ two-dimensional PSD. It reduces the exposure time per sample typically to 0.5-5 hours (depending on the particular Q -resolution and sample cross-section).

MAUD is suitable for investigation of inhomogeneities in the size range from 20-50 nm up to several micrometres and is thus complementary to conventional pin-hole SANS facilities (see e.g. SANS I at SINQ) and Bonse-Hart or focusing USANS (e.g. KWS-3 at MLZ).

Applications

Investigation of structural or compositional inhomogeneities in materials in the size range from 20-50 nm to several μm, mainly (link to publications as examples):

- porous materials ( porous glasses, plasma-sprayed ceramics, hydrated cement pastes, porous metallic membranes)

- large precipitates in alloys (gamma prime phase in superalloys, NiTi-alloys, TiAl-alloys, etc.)

- microstructure of porosity in BaTiO3 ceramics

- superplastic ceramics (see following figures)

The result of calibration measurement of monodisperse polysthyrene nanoparticles in D2O:

Layout of the instrument

The instrument uses monochromatic beam selected by bent Si 111 monochromator situated in common shielding block serving for monochromator of neighboring Neutron Optics Diffractometer. Such a construction is possible thanks to the very low absorption of silicon for thermal neutrons so that the first monochromator leaves the wavlength band for the second one almost intact.

The primary beam - common to both diffractometers at HK8 - is shaped by a collimator with dimensions optimized for the beam size and divergence employed by the SANS instrument. It contains 10 cm thick sapphire filter and a sequence of B4C and Pb inserts in order to minimize gamma and neutron background and to suppress contamination of the beam by high-order Bragg reflections. The monochromators shielding is composed from inner Pb container and outer 40 cm thick wall made of concrete filled with B4C powder. The secondary collimators are equipped with horizontally and vertically adjustable slits, which permit fine tuning of required beam size delivered to the sample area.

The remote control of the curvatures of the monochromator and analyzer crystals makes it possible to tune the instrument resolution easily in the d Q range from 10-4 to 10-3 Ă -1, according to the expected size of investigated inhomogeneities. An absolute calibration of scattering cross-sections is possible by measuring the intensity of the direct beam (no calibration samples are required). The instrument operates in fully automatic mode, including sample exchange.

All movable parts are driven by stepping motors and controlled by PC. All communication and data collection is carried out by means of a special software ReMeSys (Regulation and Measurement System). This software is under continuous development and can adopt new extensions according to the experimental needs. The experiment an be controlled by scripts written in Pascal-like language.

All movable parts are driven by stepping motors and controlled by PC. All communication and data collection is carried out by means of a special software ReMeSys (Regulation and Measurement System). This software is under continuous development and can adopt new extensions according to the experimental needs. The experiment an be controlled by scripts written in Pascal-like language.

Application range of the facility can be enhanced by several available sample environments. The list can be found here.

History

Double-bent crystal SANS diffractometer MAUD was significantly upgraded during the period 2008–2009. The upgrade significantly lowered the background and reduced unwanted higher-oder neutrons from the monochromatized beam.

Size scale of small-angle scattering

| Monochromator | bent perfect crystal Si(111), symmetric reflection | |

| Sample | maximum irradiated cross-section 4x25 mm2 | |

| Analyzer | bent perfect crystal Si 111, fully asymmetric geometry | |

| Detector | 2-dimensional position sensitive detector, 3He filled, resolution ~ 2 mm | |

| Wavelength | 2.09 Ă | |

| Neutron flux | 5x103 ÷ 5x104 n s-1 cm-2 | |

| Q-resolution | 10-4 ÷ 10-3 Ă-1 | |

| Q-range | 2x10-4 ÷ 2x10-2Ă-1 | |

| size range | 500 Ă - 2 micrometers |

To enhance the possibility to measure the samples at various conditions, several sample environments can be put on MAUD beam. For non-ambient condition studies, a vacuum furnace can be used. Samples within a set can be automatically exchanged by sample changer for up to 9 samples or sample changer 2 with 5 positions and temperature regulation (20-90 0 C). For mechanical testing, a deformation rig can be employed with maximum tensile/pressure load up to 20 kN. For measurement of anisotropic samples, a rotation table can be installed. Statical magnetic field can be applied to sample to sample either horizontally or vertically by help of electrical magnet up to 2 Tesla (20000 G).

Sample exchanger

Sample exchanger with 9 (+1Cd) sample positions enables automatic sample change and thus long runs without operator presence.

Rotation table

A table for rotation of the sample either around the axis perpendicular to the beam (omega rotation) or around the axis parallel with the beam can be set up.

Vacuum furnace

Transmission vacuum furnace with supherkanthal heating elements is capable to heat the sample up to 1400°C. During heating, the furnace is evacuated (no high vacuum, however) to prevent sample oxidation. Temperature is driven by Clare controller. An Al2O3 sample holder is available for some sample shapes. Special sample holders (M8 female thread) has to be supplied by the user.

Transmission vacuum furnace with supherkanthal heating elements is capable to heat the sample up to 1400°C. During heating, the furnace is evacuated (no high vacuum, however) to prevent sample oxidation. Temperature is driven by Clare controller. An Al2O3 sample holder is available for some sample shapes. Special sample holders (M8 female thread) has to be supplied by the user.

Deformation rig

Deformation machine for uni-axial loading (tension, pressure) ± 20 kN.

Electromagnet (DC)

Magnetic field can be applied to sample in horizontal as well as vertical direction with respect to beam. Maximum DC field is about 2T, it depends on distance between tips of cores (i.e. sample size).

Sample changer 2

Sample changer with thermal regulation from room to 90 C (+-1C) for 5 sample position. Designed for standard Hellma quartz cells (1-2 mm light path).

Do not worry - it is easy and quick process! In order to submit experimental proposer please register (or login) to CANAM user office web site. Your proposal will be evaluated by as soon as possible, usually it takes 1-2 weeks. Afterwards you disscuss the convinient dates for the beam-time with the instrumnet responsible. Please note, that there is no any dead-line for proposal submission.

It is recommended to discuss technical feasibility of the proposed experiment with instrumental responsible (Vasyl Ryukhtin, Ph.D.) before final submiting.

Beam time operation of MAUD instrument is supported by project of ministry of Youth and Education and thus it should be mentioned in publications (e.g.: SANS experiment were carried out at the CANAM infrastructure of the NPI CAS Rez supported through MŠMT project No. LM2015056).