Laboratory of Nanomaterials

Contact person: Jiří Vacík, e-mail: vacik@ujf.cas.cz

The Laboratory of Nanomaterials (Group of Materials Research with Neutron and Ion Beams - MRNIB) deals with the preparation, characterization and modification of thin films and layers of single and multilayer materials with a complex nanostructure (MAX phase, All-Solid-State Lithium Ion Batteries, hybrid systems based on metal-fullerene etc.) and with an examination of their specific physical properties. The study of nanomaterials (i.e., their preparation, research on their basic properties and possible applications) is carried out using various deposition techniques and analytical methods developed within the CANAM infrastructure at the NPI ASCR Rez.

Deposition techniques:

The laboratory of nanomaterials is equipped with several devices that enable the preparation of thin layers of single- and multi-element composites with a complex structure at the nanoscale.

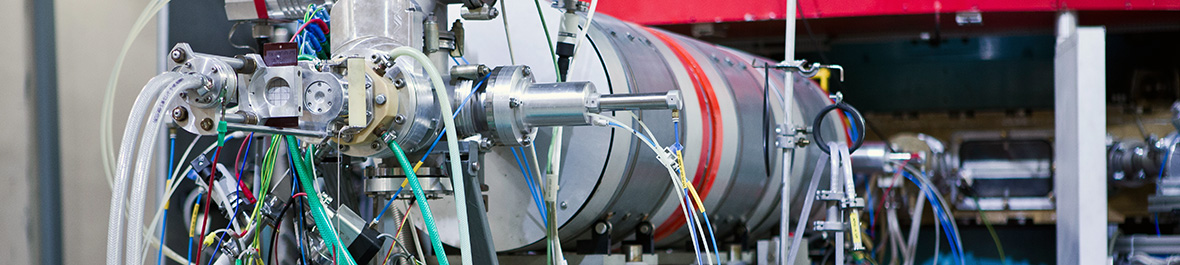

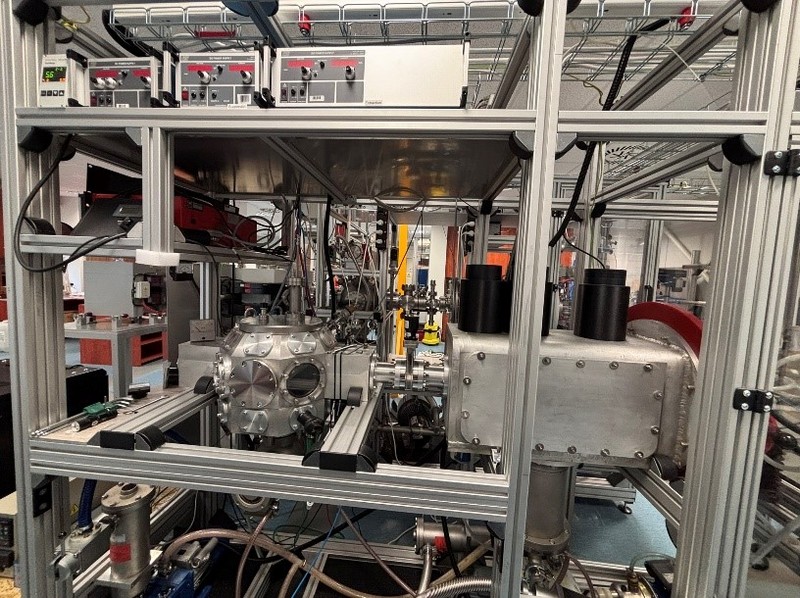

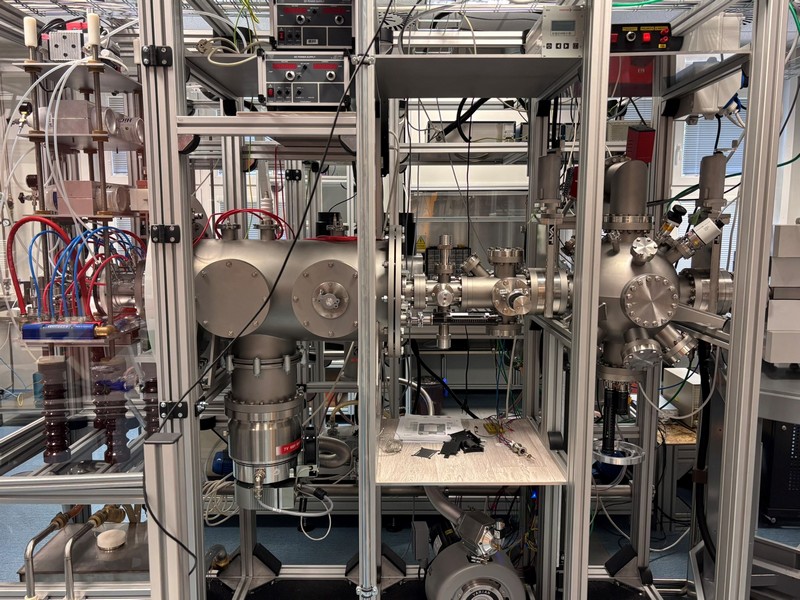

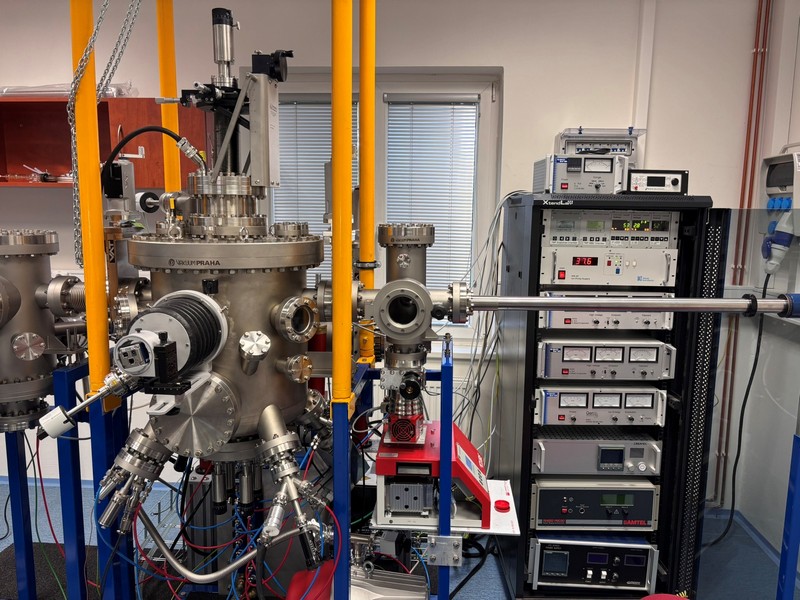

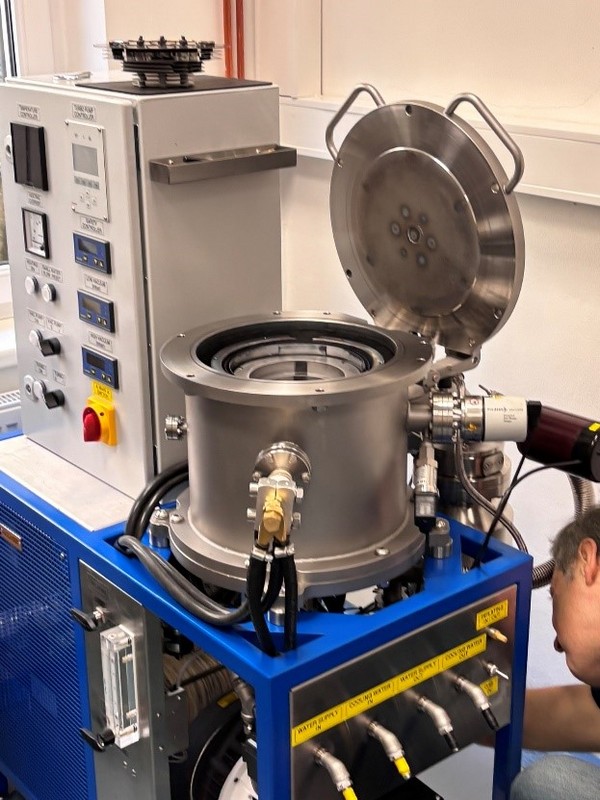

For example, using the Low Energy Ion Facility (LEIF-1) with heavy ion beams in the energy range 100 eV - 35 keV, thin hybrid layers based on carbon (fullerenes) and lithium are prepared by ion sputtering for the study of thin Li ion battery. The LEIF-2 system is intended both for the preparation of thin layers of multielement complex structures using ion sputtering method, and for their further modification by ion implantation or ion bombardment (for the controlled introduction of radiation damage). A molecular epitaxy system (MBE-1) equipped with two e-guns, a high-temperature effusion cell, and an ion gun is used to synthesize ultrathin crystalline materials. A new molecular epitaxy system (MBE-2) equipped with 3 e-guns, 2 effusion cells and an oxygen ion beam source is used to fabricate hybrid films of magnetic particles (fermions) with C-based structures. To study thin film of hybrid materials based on the combination of transition or noble metals and fullerenes, the UNIVEX system equipped with e-gun and C60 thermal vaporizer are used. The implantation of selected ions on the Tandetron accelerator (Laboratory of Tandetron) is also used for the preparation of nanostructures in thin subsurface layers of substrate materials.

LEIF 1 is equipped with a Duoplasmatron Ion Source for generating intense Ar plasma. The extraction potential can be tune from 1 to 35 keV. A beam of up to 1 mA current can be obtained at the target position, which allows ion beam sputtering and high current ion irradiation of samples to be performed. Up to 6 sputtering targets can be installed in the system to grow thin multilayers. A thermal/resistive evaporator can also be installed in the chamber for co-deposition experiments.

LEIF 2 was designed as an evolutionary and new generation LEIF device, with the installation of a multicusp ion source and new ion optics based on the Heizen Lens and deflection table, the device can produce a beam from many different gases and also from a mixture of gases (the gas can be mixed directly on the ion source the extraction potential can be tuned from 1 to 35 keV. For irradiation purposes (up to 100 keV/z) a dipole magnet and a second ion beam line are available.

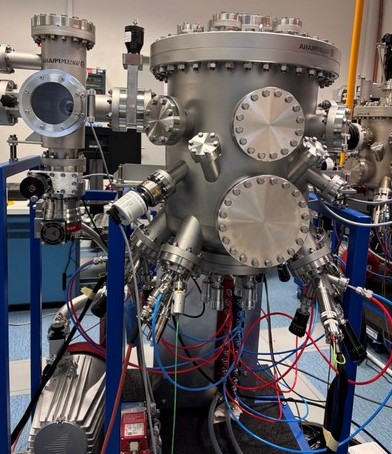

The MBE 1 system is equipped with 2 e-gun vaporizers that can operate in effusion cell mode or e-gun sputtering mode, 1 high temperature effusion cell and 1 ion source for ion deposition. The RHEED system is available to study the evolution of nanofilms during growth. The basic pressure of the system is in the range of 10-9 - 10-10 mbar.

The MBE 2 system is equipped with 3 e-gun vaporizers that can work in effusion cell mode or e-gun sputtering mode, 1 high temperature effusion cell, 1 low temperature effusion cell and 1 oxygen beam source for oxide cultivation. The basic pressure of the system is in the range of 10-9 mbar.

The MBE 2 system is equipped with 3 e-gun vaporizers that can work in effusion cell mode or e-gun sputtering mode, 1 high temperature effusion cell, 1 low temperature effusion cell and 1 oxygen beam source for oxide cultivation. The basic pressure of the system is in the range of 10-9 mbar.

Analytical methods:

The analysis of prepared (or modified) thin layers is carried out by several main methods that are available in the MRNIB laboratories operating within the CANAM infrastructure: AFM (Atomic Force Microscopy), VDP (van der Pauw) method, NBA (Neutron Beam Analysis) - NDP (Neutron Depth Profiling) and PGAA (Fast Gamma Activation Analysis).

Additional IBA (Ion Beam Analysis) methods are performed on the Tandetron accelerator (Laboratory of Tandetron).

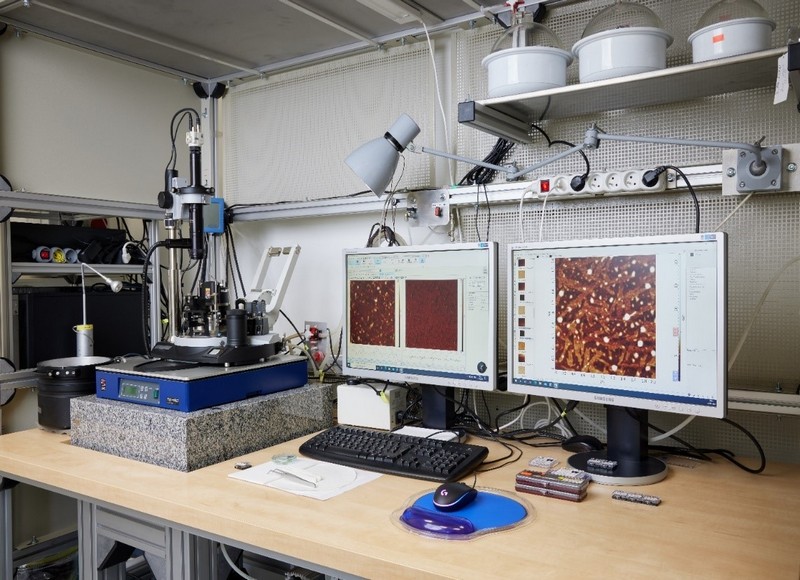

The AFM method, together with various associated modes such as MFM (Magnetic Force Microscopy), LFM (Lateral Force Microscopy) and EFM (Electric Force Microscopy), allows analysis of the main surface properties of materials (morphology, friction and wear, chemical structure of molecules, etc.) with high resolution (down to the nanometer level). The method is carried out on an NTEGRA Aura Scanning Probe Microscope (NT-MDT) in tapping and contact modes.

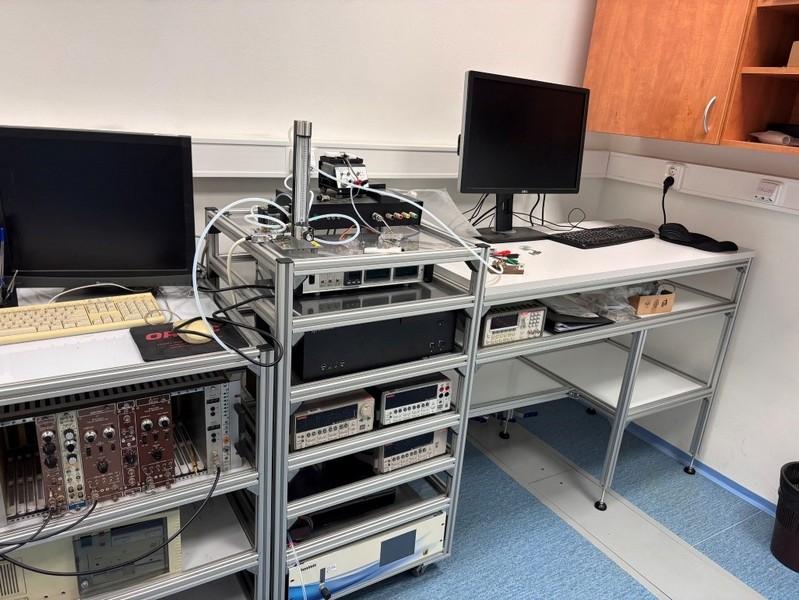

The VDP method measures the average resistivity and Hall coefficient values on thin samples by applying current and measuring the voltage along the sample perimeter.

The NDP method is intended for measuring the depth distribution of some light elements (e.g., Li, B, N) or heavy elements (e.g., Cl, Sm, Eu) in thin layers of materials. The method is based on the reaction of thermal neutrons of the type (n, alpha) with the given elements (more precisely, some of their isotopes) and measuring the residual energy of the reaction products.

The PGAA method measures gamma quanta from the neutron capture and enables to determine elements and their concentration in samples. Both methods (NDP and PGAA) are located on the short neutron guide at the horizontal channel of the LVR-15 reactor (operated by the Řež Research Center).

The IBA methods (RBS – Rutherford Backscattering, PIXE – Particle Induced X-Ray Emission, MB – Micro Beam methods, ion beam irradiation/implantation, etc.) are installed on the ion beam lines of the Tandetron 4130 MC accelerator in the Laboratory of Tandetron. The methods are available in collaboration with the Tandetron group within CANAM infrastructure projects.More about the NDP spectrometer.

AFM- NTEGRA Aura Scanning Probe Microscope (NT-MDT)

VDP Anlytical setup, measuring of gas sensing properties and sheet resistance

Sample modification methods:

Modification of the prepared samples (thin layers on substrates, thin foils, etc.) can be carried out using several methods.

By irradiating/implanting samples with ion beams with low-energy ions (up to 100 keV at LEIF-2) and high-energy ions (up to several MeV in the Tandetron accelerator) with fluences as needed.

By annealing – several ovens are available for annealing of samples in air, in inert atmosphere, in reactive atmosphere and in high vacuum.

By etching of thin polymer films – for the preparation of membranes with pores of the required size and shape, a reactor with accessories for etching using various etchants is available.

High vacuum oven up to 2300°C

Current Grants

- Title: Ferroic Multifunctionalities

Provider: MEYS CR, OP JAK

1.2024 - 30.06.2028

Principal Investigator: H. Seiner (Institute of thermomechanics AS CR)

- Title: Black metals surface-decorated by MXenes as sensitive chemiresistor layers

Provider: GA CR

1.2023 - 31.12.2025

Principal Investigator: J. Vacík (Nuclear Physics Institute AS CR)

- Title: Preparation and properties of nanoporous membranes with functionalized nanoparticles

Provider: GA CR

1.2022 - 31.12.2024

Principal Investigator: J. Vacík (Nuclear Physics Institute AS CR)

- Title: Metal-fullerene nanocomposites: synthesis, characterization and application in all-solid-state Li ion batteries

Provider: AS CR

1.2024 - 31.12.2025

Principal Investigator: G. Ceccio (Nuclear Physics Institute AS CR)